Originally posted by Dave

That's all I am saying. Don't read this Bill.

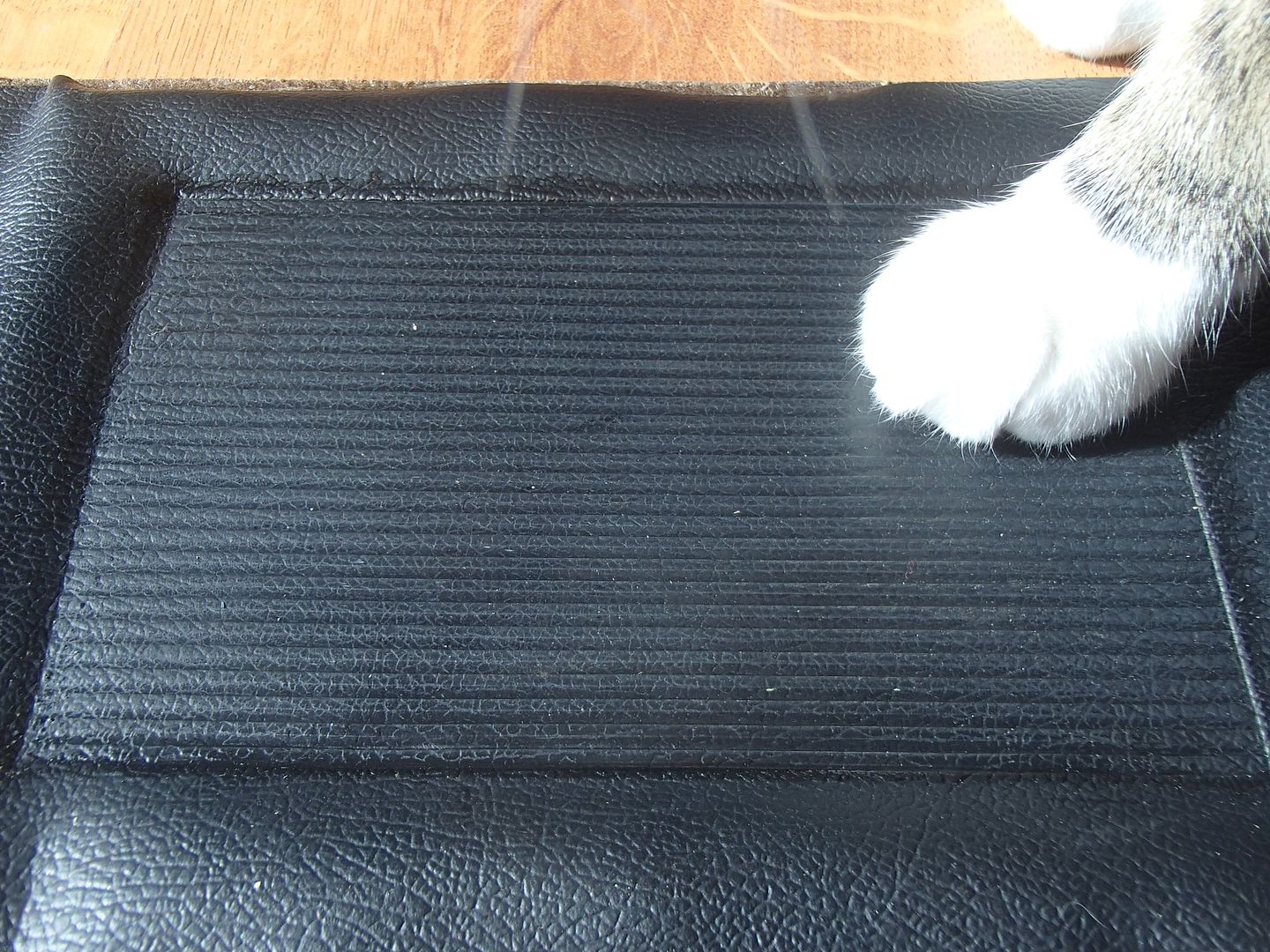

That's all I am saying. Don't read this Bill.  PS Sadie is just fine.

PS Sadie is just fine.

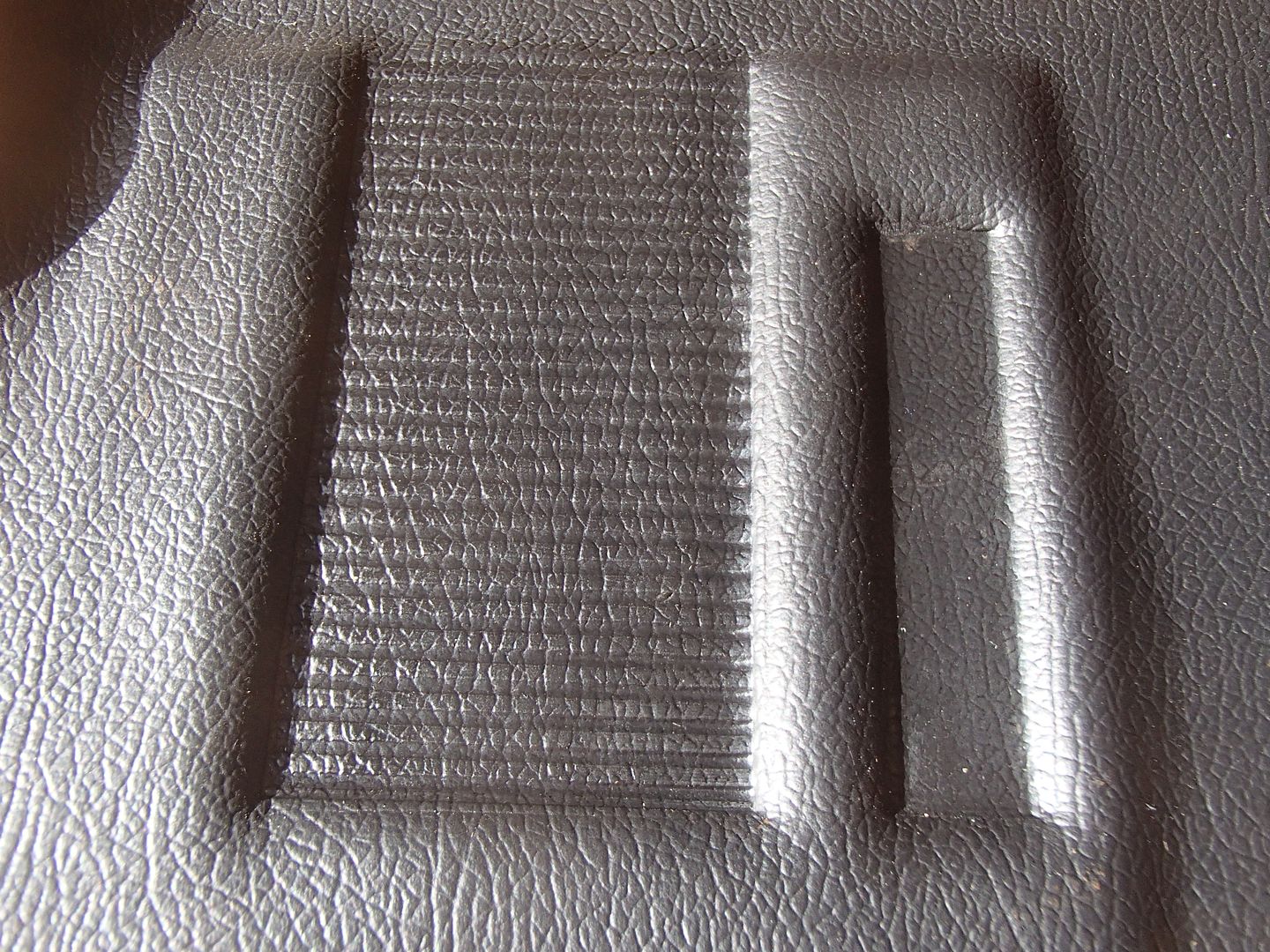

I have the front section fitted and trimmed.

I have the front section fitted and trimmed.

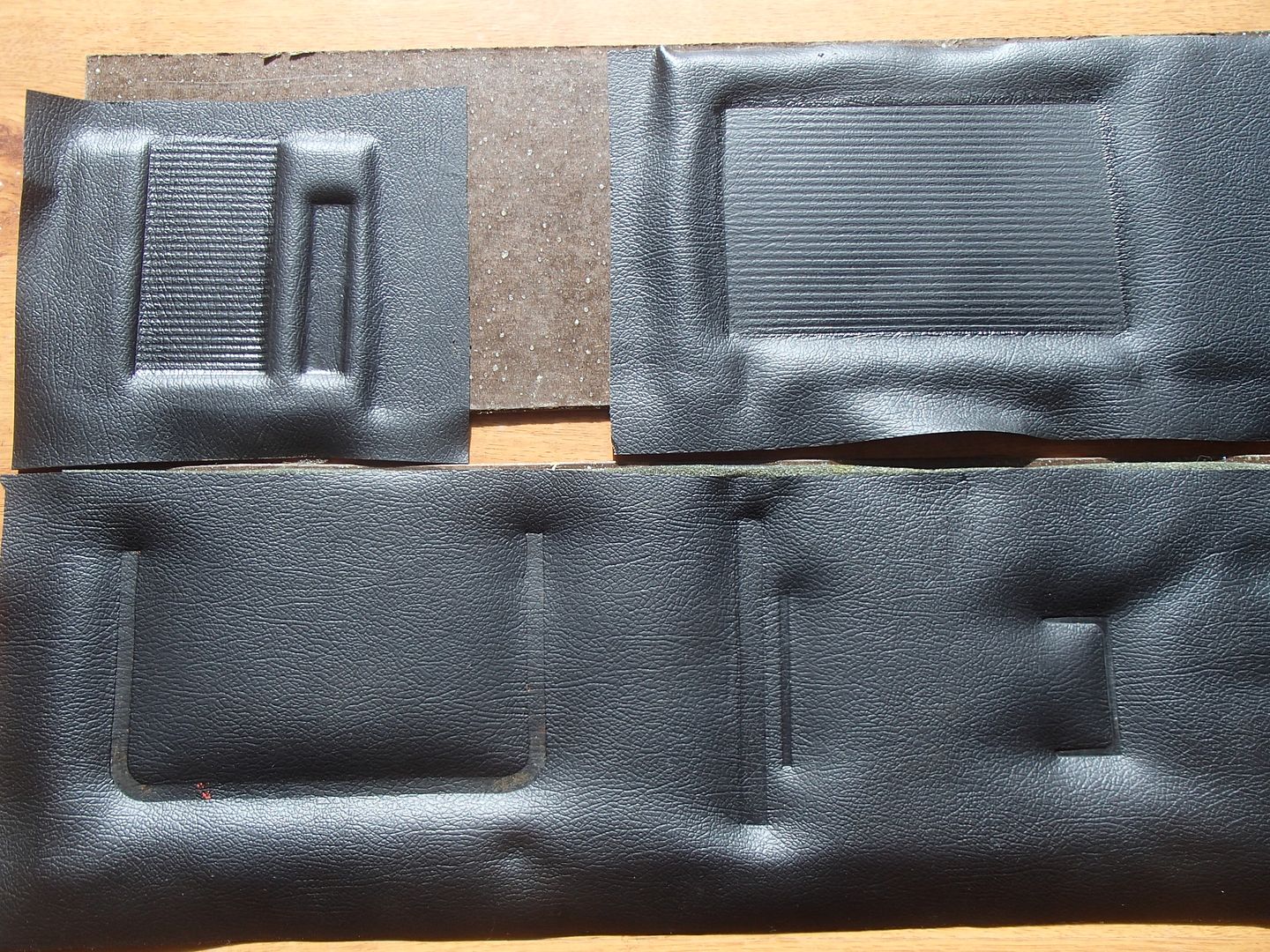

So I am going to experiment with temperatures and exposure times using much smaller samples and my wifes oven. I hope she does not read this.

So I am going to experiment with temperatures and exposure times using much smaller samples and my wifes oven. I hope she does not read this.  I can at least get that figured out. I will then probably buy a beater stove and scavenge two upper round burners and the controls and make my own oven.

I can at least get that figured out. I will then probably buy a beater stove and scavenge two upper round burners and the controls and make my own oven.

Comment